If you have ever used the dome feature and found that the dome shape is pointed, try unticking the continuous dome box. This was applied to both ends of the sweep, the faces were then extended with an extrusion and a dome was applied to each to cap the ends. I used the direct editing tab and move face to do this, with rotate selected I could tilt the face to the desired angle. The ends of the sweep needed to be extended but before this I needed to change the angle of the faces. For these I modelled a spiral using a helix and a circular sweep, without a taper, which wrapped around the wire loop. The main part was modelled using a sweep and twisting the profile along the path, the barbed wire parts were slightly more complex. The next part to model is the loop of barbed wire. Once the bat is modelled, I added a wooden appearance to it, firstly for my rendering of the part, but also this makes the part easier to see when mating wire parts to it in the assembly later on. One tip for this part, I advise adding any fillets after you have revolved the part, this makes it easier to adjust the original sketch, but also allowed me to add asymmetric fillets. Thank you friends.Welcome to this SOLIDWORKS tutorial for a zombie bat, to begin this assembly, I start by creating a baseball bats profile for revolving.

#Solidworks assembly free#

If you found this SolidWorks Tutorial useful, feel free to share to friends, like and comment.

#Solidworks assembly how to#

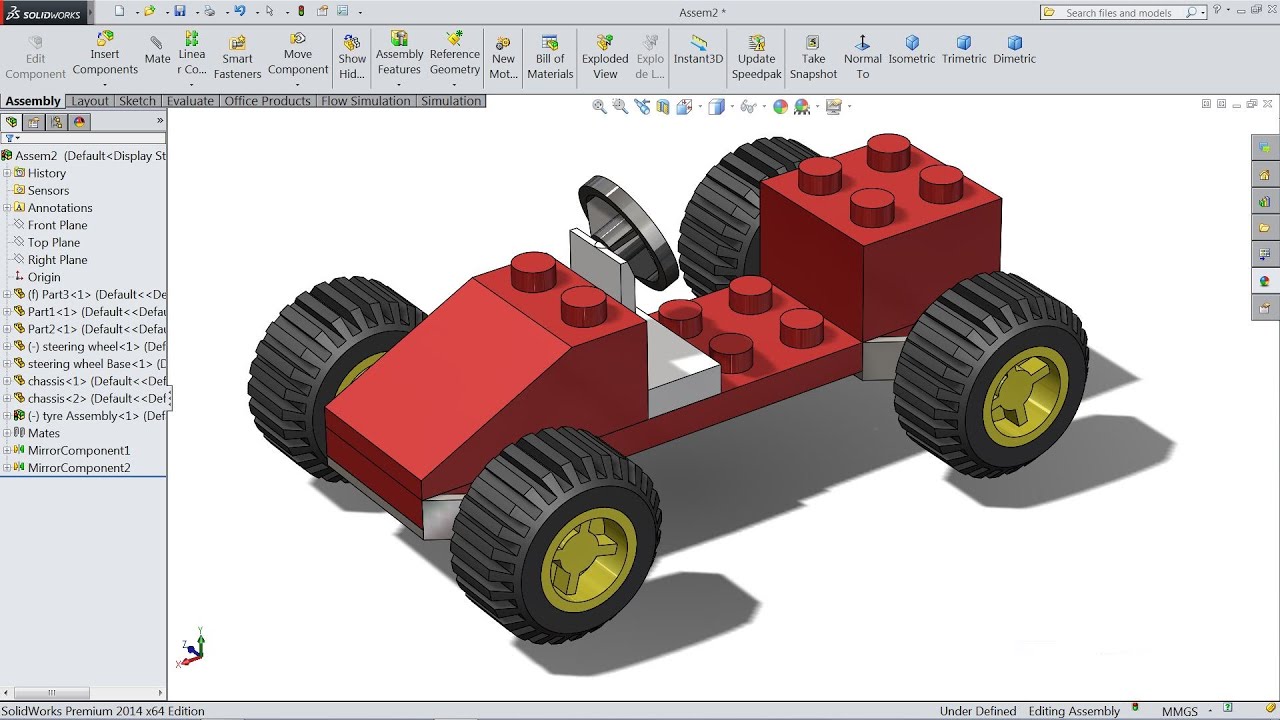

In the next tutorial, you are going to learn how to assemble these two components using the mates feature. Save the assembly file by using the “save” command for future solidworks assembly tutorials.

So that you can learn different types of mates and its application in SolidWorks assembly.

These are the very basic tutorial, you should have better idea on it. This way you can fix component or float it in solidworks assemebly interface. Select fix or float from the appearing menu as per your requirement. Select and right click on the component’s name for changing the fix or float condition. To change the fix or float, go to featuremanager deign tree. You can see (-) before its name in Featuresmanager design tree. That means, you can move, rotate or having degrees of freedom in assembly area. So, insert another component and place it anywhere in graphics area. You can also make it float by accessing the Featuresmanager design tree. This way you can fix component to origin in assembly area.

So, it is better to place to origin.Ĭlick on the origin to select the fix point as origin. It should got fix with respect to the origin of the graphics area. You can fix component anywhere in graphics area. One of the part is stationary or base part and other one is moving part into it.įirst, you have insert stationary part into the assembly interface and will get automatically fix by SolidWorks. How to Fix Component in SolidWorks AssemblyĪlready created two components to show the fix or float feature in assembly. These are the main factors should remember before applying fix component in SolidWorks Assembly. Single Instance of Component Pattern Can’t be Fixed So always insert component which is base or stationary part in your model. In SolidWorks assembly, when you first insert a component will get automatically fix by default. Once, you fix component, it should mentioned (f) in Featuresmanager design tree, before its name. It will be very helpful for adding other mate functions and constrains. It is best to fix base part to origin of the assembly graphics area. You should consider the component which is stationary or fix part in design. Important Factors should remember before fixing component:- 1. Important Factors should remember before fixing component:.

0 kommentar(er)

0 kommentar(er)